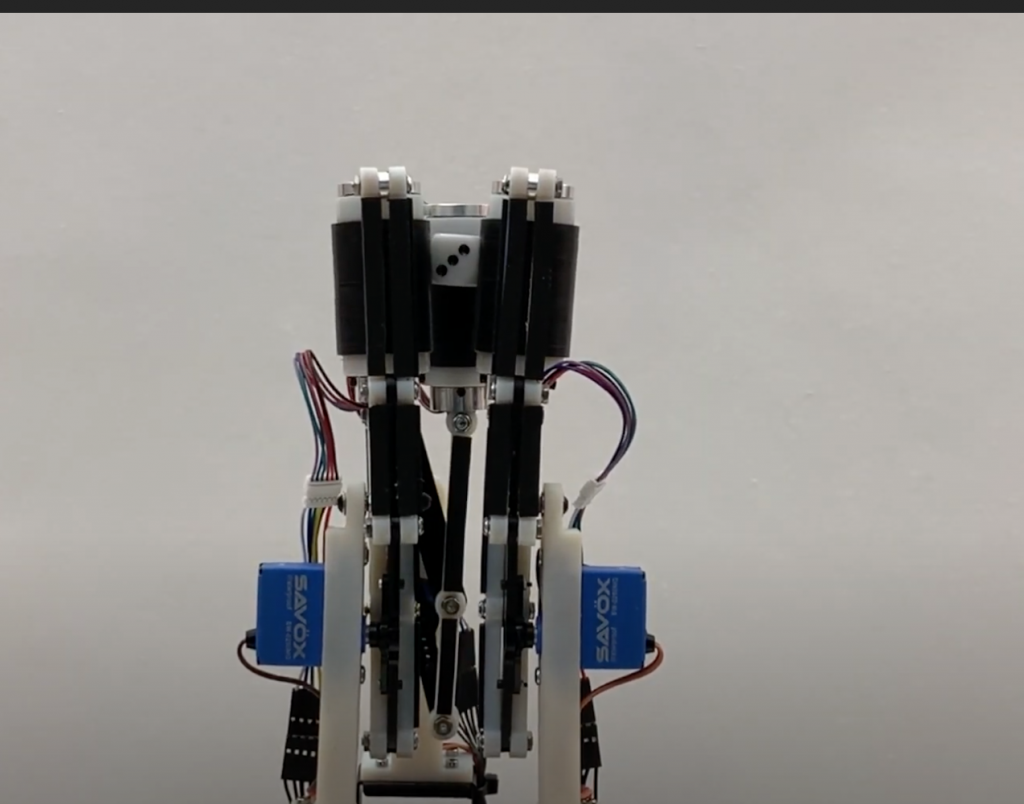

A roller-based dexterous hand for object grasping and within-hand manipulation is just one advance that makes robots more useful to industry.

Robotics, IoT Poised for Explosive Growth Due to Advances

For the first time since the 1961 debut of GM’s Unimate, regarded as the first industrial robot, the robotics field is once again transforming world economies.

Only this time, the impact will expand because of the COVID-19 pandemic, which has helped push automation forward into manufacturing, fulfillment centers, retail, and restaurants. Also, robots are being adopted widely in nonindustrial offices, hospitals, and schools, as well as in warehouses, fulfillment centers, and small manufacturing centers. They are transporting goods on the road and in the air.

According to a comprehensive guide on zdnet.com, robots are even adapting better to interacting with humans.

The guide, written for enterprise companies, addresses a sector that could reach $210 billion by 2025 (a CAGR of 26%), one whose relevance to commerce and day-to-day life in the coming decades cannot be overstated.

Some of the highlights of the guide include:

Four reasons why the field has advanced in recent years:

- Falling sensor prices

- Open-source development

- Rapid prototyping

- Convergence of disparate technologies

By 2025 there will be 100 billion Internet of Things connected devices generating revenue of $10 trillion. For the first time, sensors that capture and send data related to pressure, torque, and position are dirt cheap, leading to a boom in robotics development.

Open-source development

A 2009 paper presented at the IEEE International Conference on Robotics and Automation (ICRA) introduced the Robotic Operating System (ROS) to the world, the first standard OS for robotics development. It is free, open-source, flexible and releases developers from the time-prohibitive task of developing an OS. Others have adapted and added to its functionality.

The Impact of COVID-19

The impact COVID-19 and the massive shutdowns and layoffs and operations changes are a major motivator for businesses to adopt robotics.

“If the seeds of a robotic revolution have been sprouting for over a decade, going back to research lab Willow Garage and the groundbreaking robotics research that began coming out of DARPA contests in the early-2000s, COVID-19 may prove to be an accelerant.”

Undoubtedly, robots are replacing workers who are forced to stay home or who are sick. Manufacturers are finding that they’re saving money, too.

“Most of the automation equipment in the industry is used to replace manual labor in repetitive and simple processes. However, in the future, we believe collaborative robots will increasingly participate in complex production processes,” says Felix Yang, Accelerated Digitalization Lead, Greater China at SF DHL China, a ForwardX customer and the largest third-party logistics provider in the world.

The guide explores in-depth how robots have become an intricate part of business.

read more at zdnet.com

Leave A Comment