Robot Roundup: Tech Listens with Locust Ear, Fixes Other Robots & Brews Beer

For our technology round-up this week Seeflection.com is taking a look at robots. In particular, the advancement of the robot uses and testing. We will start with what has to be the weirdest robot story we found. Amanda Kooser writes in cnet.com about a robot that listens with a dead locust’s ear. Yes, you read that right.

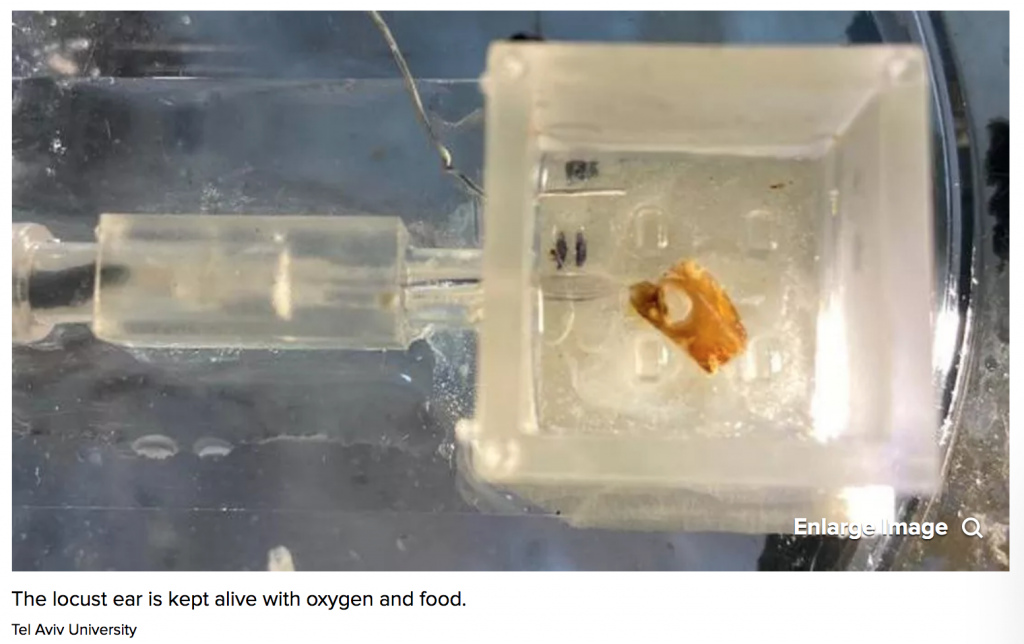

Beetles wearing camera backpacks and moths driving tiny cars are the results of real insect experiments. A team of researchers at Tel Aviv University in Israel has taken a different path and created a bio-hybrid robot that “hears” through the ear of a dead locust, a type of grasshopper.

The robot receives electrical signals through the ear. It’s programmed to respond to sounds, so one clap triggers the robot to move forward. Two claps send it backward.

The team published a study on the robot this year in the journal Sensors.

“Our task was to replace the robot’s electronic microphone with a dead insect’s ear, use the ear’s ability to detect the electrical signals from the environment, in this case vibrations in the air, and, using a special chip, convert the insect input to that of the robot,” study co-author Ben Maoz in a Tel Aviv University statement on Tuesday.

The researchers hope Ear-Bot is just the beginning, and that it could lead to advancements in integrating other biological systems—like noses that can sniff out drugs or explosives—into robots. “Nature is much more advanced than we are,” Maoz said, “so we should use it.”

read more at cnet.com

Robot, Heal Thyself

As the world contemplates ways to deploy robots to help with hazardous tasks such as large-scale cleanups or search and rescue missions, scientists are also second-guessing how to fix machines if they come into harm’s way. Jelly-like polymers used to create robotic hands can repair themselves after a violent infliction. And, “biological” androids made from stem cells can regenerate and stitch back together when sliced. The latest breakthrough involves tiny microbots that can magnetically “heal” themselves on the fly after breaking apart, without help from humans.

Engadget.com had the story regarding the 2cm long robots that scientists actually cut in half and then watched as the polymer healed itself. It is thought that the process will lead to larger bots being able to heal themselves as well. Imagine the storyline of that movie.

read more engadget.com

Brewery Introduces Robots On The Production Line

Heineken beer has long held a major portion of the Dutch beer market and it has several plants around the world. Now it wants to make those plants safer and more employee-friendly with the use of robotics. Robohub.org has an interesting story this week about robots and how the beer makers are bringing them more on board.

From small breweries to mega-plants, its logistics and production processes are increasingly complex and its machinery ever more advanced.

“The environment is constantly changing and the robot has to be able to respond immediately.” says Shobhit Yadav, mechatronics engineer smart industries and robotics at TNO.

The robots took over repetitive tasks like picking up bottles that fell over on the assembly line and righting them so that employees were freed from boring work and were able to focus on more challenging tasks and roles.

The guys at Heineken have nothing but praise for the innovative collaboration with TNO and RoboHouse.

Dennis says, “The great thing is that all project partners were in it to learn something. At RoboHouse, we had access to the expertise of robotics engineers and state-of-the-art technologies like robotic arms. We supplied the bottle conveyor ourselves and TNO also added knowledge to the mix. It is an accessible way to do research and experiment. This would be a lot more difficult with a business case, which must involve an operational advantage from the start.”

“Through close cooperation, we really developed a joint product.” noted Bas van Mil, mechanical engineer and robot gripper expert at RoboHouse

The Heineken robots are liked by employees because it optimizes the process, makes it safer and reduces the workload.

read more at robohub.org

Leave A Comment