Astronauts in Orbit Will Make Parts, Even Satellites

What happens when something breaks aboard the International Space Station? In the past, spare parts had to be sent on resupply missions, which were expensive and time-consuming. Former NASA intern Jason Dunn saw a better option and founded Made in Space. He and his team developed a cutting-edge 3-D printer that now lives on the ISS, allowing astronauts to create new supplies in orbit.

Dunn hopes their invention will spark a new era of dramatic progress in space exploration. Production company Freethink documents the work of Made in Space in this episode from the National Geographic series, The New Space Race.

The Made in Space company had such success with their 3-D printer, they decided to upgrade it to a full factory orbiting in space.

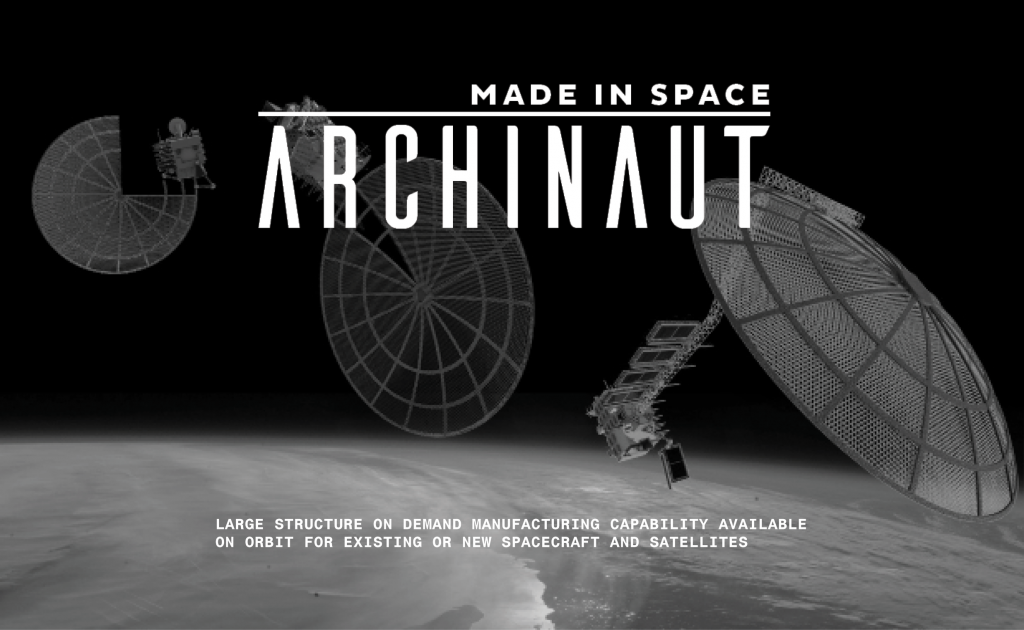

They are developing the Archinaut, a floating factory, that will manufacture heavy equipment⎯even full satellites⎯in orbit.

The Archinaut is composed of an industrial sized 3-D printer, cartridges full of plastics and alloys, and robotic arms programmed to assemble the big items extruded by the printer without any human supervision. All of the Archinaut’s components can survive in microgravity and harsh conditions like lunar dust storms and extreme temperatures.

Reporters visited the Made in Space headquarters at Moffett Field in Mountain View, California (NASA Research Park) to get a look at the Archinaut as engineers prepared it for a thermal vacuum test and to speak with Archinaut’s creators. Aaron Kemmer, Made in Space’s co-founder and chairman, said the company plans to have the Archinaut launched and cranking out large items like trusses and reflectors for satellites within five years.

Eric Joyce, a project manager, added that the Archinaut should also be able to help astronauts repair their spaceships without having to improvise materials and take the kinds of risks that the Apollo 13 crew did back in 1970.

Those systems were used to make items that researchers aboard the ISS needed to conduct science experiments, among other things. Today, it’s expensive, and challenging to get even small things into space. Every object must be strong and compact enough to fit into a launch vehicle. Max Fagin, an aerospace engineer at Made in Space, said most of those items can be made 10 times lighter and 10 times cheaper, if they don’t need to withstand the “shake, rattle and roll” of a launch.

“It’s an absolutely essential step in the future of our species to inhabit every environment in the solar system that we can,” Fagin said. “It’s not going to be done by importing everything you need from where you came from. It’s going to be done by manufacturing what you need where you need it.”

They will find materials to build with in space on the planets or moons they visit. A whole universe of elements and minerals could be discovered.

View the full Nat Geo video here.

Leave A Comment