Tech Key to End of Copying & 3D Print Fraud

HP’s forward-thinking CTO Shane Wall recently spoke with Forbes’ Amy Feldman at the company’s Palo Alto headquarters, describing how blockchain technology can revolutionize the manufacturing industry by immutably linking parts manufacturing, intellectual property rights and company supply chains together on the blockchain.

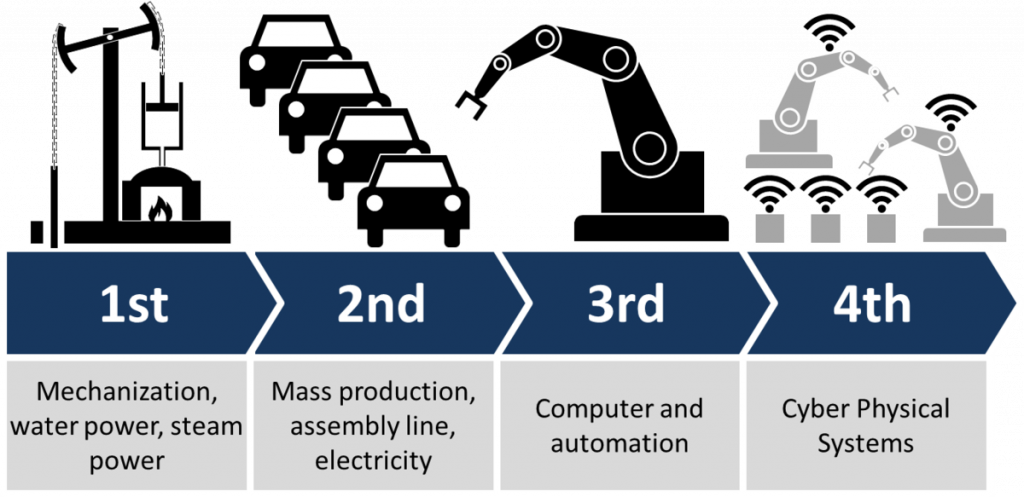

Known for its consumer computers and printer technology, Fortune 50 company HP has been making increasing strides in 3D printing and other emergent tech breakthroughs that will empower what industry analysts call a new data-rich “Industry 4.0” enmeshing AI, robotics, VR/AR, big data, blockchain and other 21st-century tools. As CTO and head of HP Labs, Wall believes that the future of manufacturing will incorporate 3D printing and blockchain to authenticate and transform how parts are made, licensed and accounted for.

In contrast to traditional network infrastructures, blockchains are built around distributed, decentralized computing nodes that maintain a consistent, open ledger of data, maintaining a shared consensus record upon which data or tokenized assets can be stored and transacted. Describing the technology as “interesting” and “disruptive,” Wall foresees that blockchain “will radically change counterfeiting of parts, which is obviously a huge issue today.”

Industry is presently at the cusp of a fourth revolution incorporating technological innovations such as blockchain and 3D printing. Via Christoph Roser.

According to Wall, the most promising intersection between blockchain and manufacturing lies in 3D printing, where parts would be digitally created and then “printed” on site. “The printer prints it out and modifies the blockchain. After it completes the part, it updates the blockchain, and says, one is printed and you only have 999,999 you can do.” By encoding information about an individual part onto a blockchain, manufacturers, customers and intermediaries can store and track each part and guarantee origin.

“I can actually track every single physical part,” says Wall, who is testing the technology but estimates that such industrial-scale applications of blockchain are probably two to five years in the future. To link the data on a blockchain permanently to an individual physical part, Wall suggests that minuscule digital “watermarks” might be generated on each part during printing or manufacture.

As 3D printing and blockchain gain traction and digital manufacturing becomes predominant, Wall told Forbes that the creation of an industry-wide standard could guarantee the provenance and authenticity of parts worldwide across different industries and manufacturers.

Leave A Comment