/cdn.vox-cdn.com/uploads/chorus_image/image/59430959/Image_1.0.jpg)

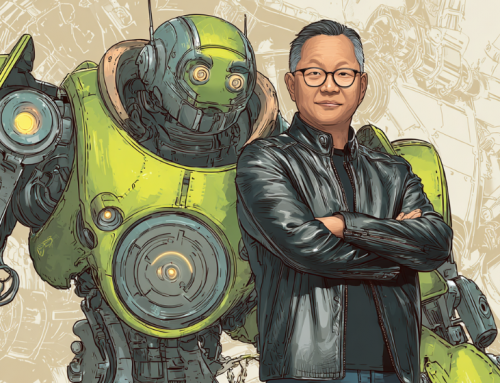

Assistant professor Pham Quang Cuong (L) and researcher fellow Francisco Suárez-Ruiz (R) from NTU Singapore pose next to a robot arm and the IKEA chair it helped assemble. Image: Nanyang Technological University (NTU), Singapore

Today the Furniture, Tomorrow the World

Who among us has not turned into a blubbering, anger-driven idiot trying to assemble the completely logical Ikea desk, nightstand or bookcase? It should be easy peasy, but it’s not for most of us until after having to undo 10 screws, and turn the whole piece over and inside out three times. Some consumers just don’t have the gift of reading even the easiest blueprint.

Ikea’s blueprints could be considered simple, if you’re an engineer. Now imagine teaching a computer-driven pair of robotic arms to read the blueprints

In a paper published today in Science Robotics, researchers from Nanyang Technological University in Singapore describe how they instructed a pair of industrial robot arms to put together a Stefan chair from Ikea “with no special provisions for robotic assembly.” The arms used 3D cameras to identify and track individual pieces, and force sensors to make sure they weren’t crushing anything.

All in all, assembly of the chair took around 20 minutes. So, not as fast as a human, but not too shabby. The work is a step up from previous Ikea assembly systems, says Dr. Francisco Suárez-Ruiz, one of the researchers involved. Compared to MIT’s IkeaBot system, the furniture being assembled was more complex. Compared to work done by the same Singapore team in 2015, the assembly is more autonomous.

An article written by James Vincent for The Verge.com describes how the robots building the Ikea pieces were given instructions and other helping features before being turned loose. Even with training, they weren’t always successful, as you can see in the video of bloopers below.

Two points in the article should bring some measure of relief to working class men and women in factory assembly. First, the robots are pretty good when given a head start and pre-planned hands with which to manipulate a product, however, humans still have the advantage when given on-the-spot problems to solve. The robots are improving daily, but only at this narrow function.

Second, there’s still room for improvement. This new Ikea assembly bot is not completely autonomous. The system was preprogrammed with both 3D images of the chair’s components and with assembly instructions. (The robots autonomously plan each individual motion, but not what order to make them in or where each part should to go.) In the paper, the researchers suggest that future upgrades work all this information out for themselves by scanning the assembly manual.

Still, robots getting better at assembling Ikea furniture means robots are getting better at jobs that can currently only be done by humans. Obviously, how exactly systems like this get implemented into the workplace (and whether that involves job loss) is something that varies by industry and company.

“In the future, we envision that robots like this should be helping with tedious or dangerous tasks,” Suárez-Ruiz told The Verge. “There are so many industries where these skills would be useful, like logistics, or packing for e-commerce companies.” Ikea furniture is just the start.